Bogie workshop & train maintenance systems

Overview

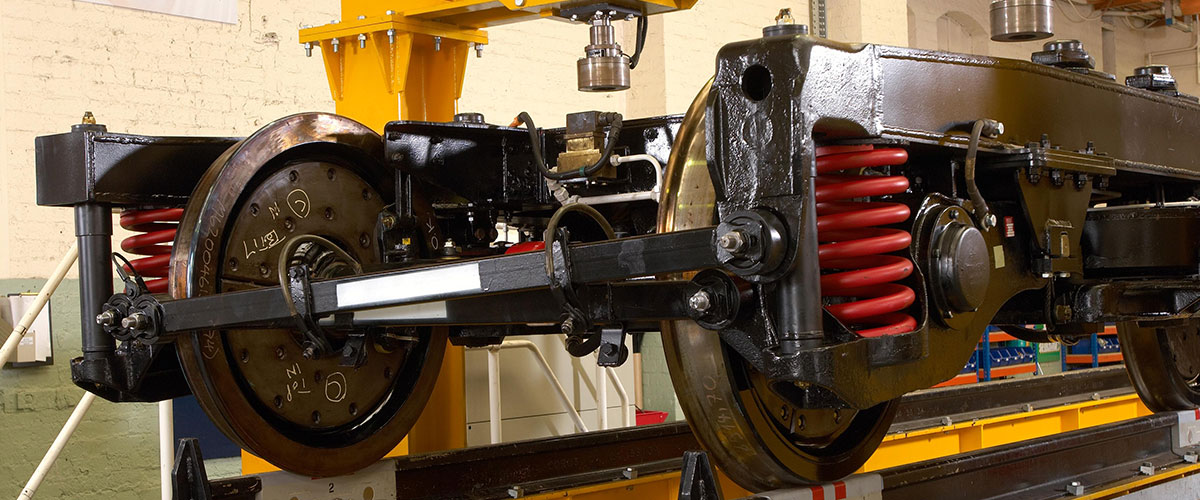

Our Bogie Workshop Systems can be integrated into any type of new or existing bogie test machines which are used to set up bogies correctly after being built, repaired or refurbished. Highly suited to bogie weighing our TrackCell (and RamCell) system can offer a complete bogie weight measurement through integrated weighing technology. The rail vehicle bogies are pressed via hydraulic test rigs to simulate train loads. This identifies discrepancies in wheel weights which can be adjusted prior to being applied to the carriage or wagon. Consequently this increases the lifespan of wheels and bogies whilst substantially improving the ride of the vehicle.

Our innovatively designed train weighing loadcell’s (TrackCells), take the hard work out of building accurate, cost effective wheel and axle weigh stations for different types of locomotives and rolling stock. The TrackCell system is predominately designed to provide highly accurate static weighing data whilst minimising disturbance on installation, which is ideal for manufacturing workshops, maintenance workshops and rail load outs.

Our TrackCell’s provide individual wheel weights for bogies in production and can reports on axles, bogies and wagons. Each system is supplied in multiples of four, therefore allowing the weighing of up to 8 axles simultaneously. Our TrackCell’s weigh in 5kg increments which provides sufficient ‘sensitivity’ when weighing bogies for a variety of different rail vehicles and helpful for weighing either partially or fully assembled bogies. Our RamCell’s and TrackCell’s can also use our PTW indicator or ptwX software which provides accurate weighing data for rail workshops and can be integrated into any type of bogies.

Our Bogie Workshop Systems have helped advance the technology in bogie manufacturing for the rail industry. Our systems give bogie manufacturers the opportunity to see weight distribution throughout the bogie so they can make the necessary adjustments and understand the condition of wheelsets and other bogie components.

Key Benefits of Bogie Workshop Systems

- Easy to install.

- User friendly.

- Suits all rail types.

- Heavy duty/overload protection.

- Wheel by wheel weighing.

- Factory pre-calibration.

- Enhances Bogie quality control.

- Minimal foundations needed.

Technical specifications

| Item | Specification |

|---|---|

| Length | 502mm (other sizes are available) |

| Power Supply | 110 – 240VAC / 12VDC |

| Increment size | 5kg |

| Capacity | 15t per wheel (different capacities are available) |

| Material | High quality tool steel |

| Temperature range | -30C to +70C |