Calibration Solutions Designed to Ensure Your Weighing Systems Perform

Built on Trusted Metrology Principles

With over 30 years of hands-on expertise, we bring precision, compliance and peace of mind to every rail scale we support.

A calibration compares your equipment’s readings against a verified reference standard. This identifies and corrects any deviation, ensuring your weighing system consistently delivers reliable and accurate results.

To maintain the highest standards, we utilise a reference load cell that an independent UKAS-accredited laboratory regularly tests. This involves a highly accurate deadweight machine, ensuring that every calibration we perform is based on trusted metrology principles.

The Benefits of a Regular Calibration

Reliable Measurements

Accurate, consistent measurements are essential for safe and efficient train weighing. Regular calibration ensures confidence in your data.

Peak Performance

Routine calibrations help keep your equipment running optimally. As a result, they reduce unexpected downtime and extend your system’s lifespan.

Longevity

Many PTW systems installed as early as 1997 are still operating reliably today—thanks in part to scheduled calibrations, servicing and maintenance.

Tailored Calibration Solutions

Our calibration services are flexible and built around your operational needs. By working closely with you, we develop a service plan based on your equipment’s usage, internal quality procedures and accuracy requirements.

Whether you need an onsite calibration in the UK or abroad, or prefer to send your weighing system to our in-house facility, our experienced team can adapt without delay.

To give you flexibility, we also offer precision calibration rigs, allowing you to perform in-house calibrations on your own schedule.

Precision, Compliance, Documentation

Every calibration we conduct is performed using UKAS-traceable equipment, ensuring compliance with international metrology standards. Furthermore, the process is efficient. Most calibrations are completed in just a few hours and do not require test trains.

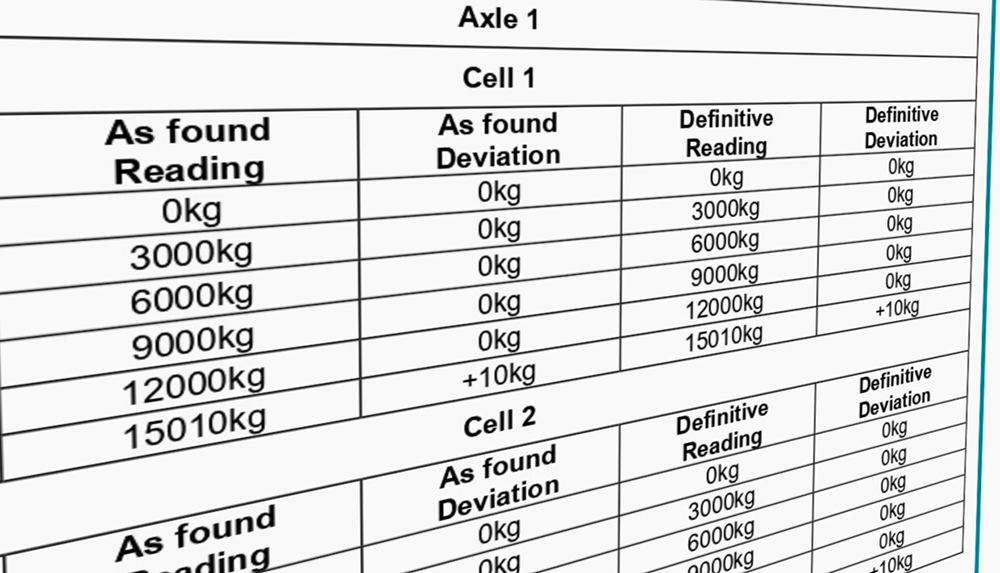

We also provide a detailed calibration certificate for full traceability, which includes:

- “As-Found” and “Definitive” readings.

- Adjustments made during calibration.

- Reference equipment details.

This documentation gives you clear, auditable assurance in the quality of your weighing results.

Common Questions About Our Calibration Services

// Supporting accuracy and compliance

Why partner with Weighwell?

Partnering with Weighwell means working with a provider who understands the importance of accuracy in every weighing task.

Our calibration services maintain the performance of your equipment, helping you operate safely, efficiently and with confidence.