Improving Quality Control & Precise Weight Distribution During Bogie Production, Overhaul & Repair

Designed to integrate with new or existing workshop infrastructure

Originally developed for use under a bogie press, the TrackCell™ Bogie Workshop System integrates easily with both new and existing press setups. In addition, it can be used to statically weigh individual axles, railcars or locomotives—capturing precise data in a single movement.

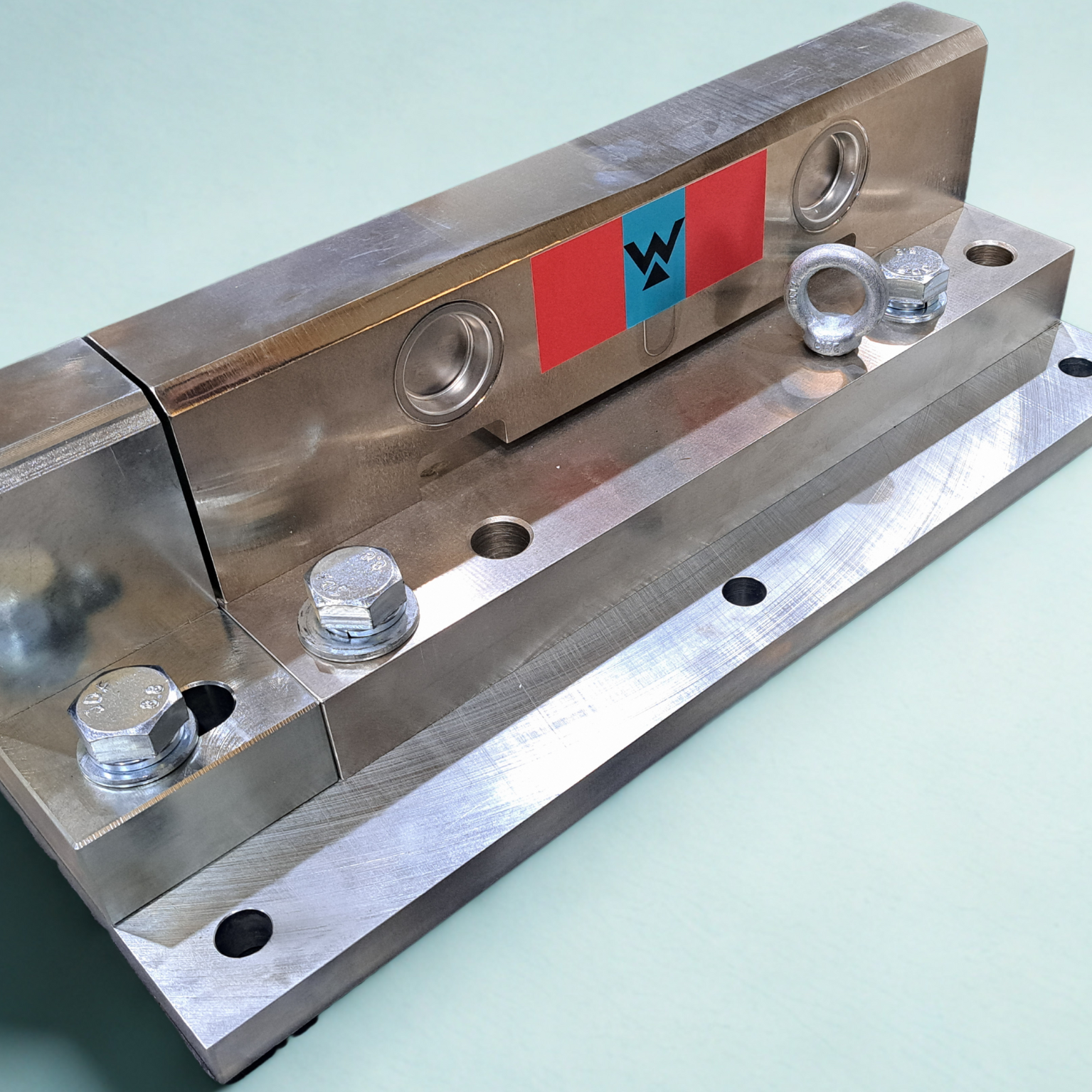

Installed permanently into the track, the system requires only minimal track modifications and can be fully installed in just a few hours. The system uses precision-engineered loadcells that weigh directly on the wheel tyre, delivering consistent and reliable results.

The Bogie Workshop System integrates seamlessly with our static weighing interfaces either a digital indicator or PC-based software. These user-friendly interfaces provide clear, real-time data, enabling engineers to see individual wheel weights and make informed adjustments with confidence.

Key Features of Our Bogie Workshop System

Replaces the existing rail

This system replaces rail sections with precision-engineered loadcells, maintaining a consistent track height.

Multi-gauge flexibility

Optional multi-gauge setups make the system ideal for workshops handling various rail vehicle types across different track gauges.

Self-installation option

The system comes complete with all components, instructions and technical support, making in-house setup straightforward.

Adjustable track section

Using an adjustable track section, the system can accommodate different bogie lengths and wheel centre distances.

Technical Specifications

| Accuracy/Repeatability | Achievable accuracy of 0.2% with a TrackCell™ under each axle. |

| Length | 502mm. |

| Weighing Capacity | 15,000kg per wheel (heavier capacities are available). |

| Power Requirements | Battery or mains power connection. |

| Transmission Range | Up to 15m per axle (wired) or 60m (wireless in urban environments). |

| Temperature Range | Operates between -30°C and +70°C. |

// Precision weighing within your workshop

Ready to Revolutionise Your Depot Workshop Operations?

The TrackCell™ Bogie Workshop System offers far more than just bogie weighing. It delivers dependable precision with minimal disruption, making it a trusted choice for weighing railcars, locomotives and more—all within your workshop environment.